Our Aluminum die castings represent the pinnacle of precision manufacturing, designed to meet the rigorous demands of global industrial applications. As a leading provider of Aluminum Castings, we specialize in producing high-quality components through advanced Die Casting techniques, ensuring superior durability, dimensional accuracy, and surface finish. Whether for automotive, aerospace, electronics, or industrial machinery, our Aluminum Die Casting products deliver consistent performance and reliability, backed by rigorous quality control and continuous process optimization.

- Model No.: NDC10-330

- Brand: Niceday

- Material: High-grade Aluminum Alloy (Customizable based on application requirements)

- Casting Type: Cold Chamber Die Casting

- Surface Treatment Compatibility: Electroplating, Painting, Anodizing

- Precision Tolerance: ±0.02mm (Based on part complexity)

- Weight Range: Customizable (Typically 50g – 5kg)

- Quality Standard: ISO 9001, IATF 16949 (Automotive Grade)

- Applicable Industries: Automotive, Electronics, Aerospace, Medical Equipment, Industrial Machinery

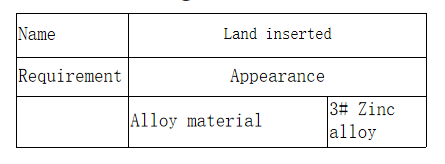

Figure 1: Detailed view of aluminum die casting structure, highlighting gating system and cavity design for optimal metal flow.

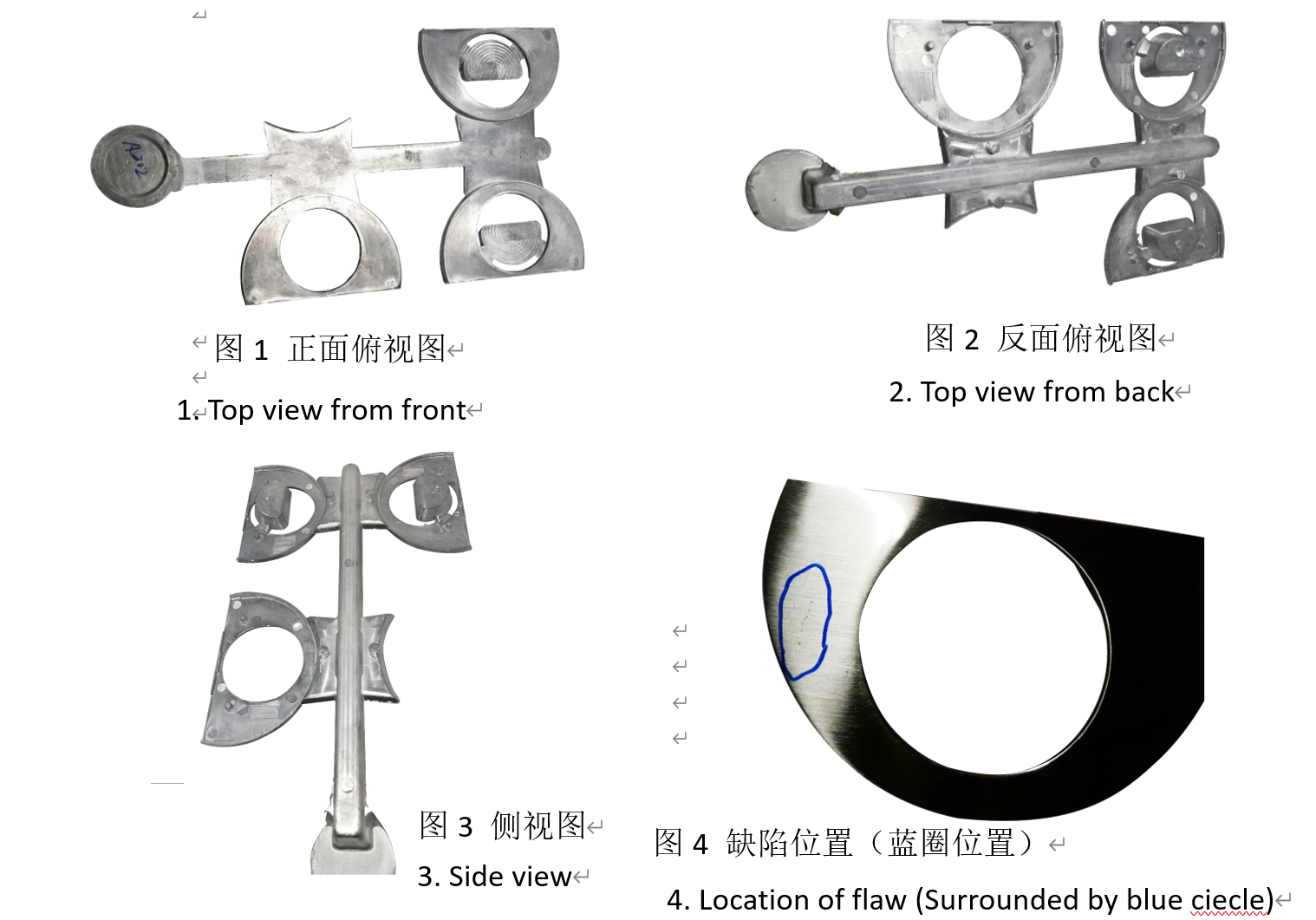

Figure 2: Finished aluminum die casting product demonstrating superior surface finish, ideal for electroplating and other post-processing.

Figure 3: Cross-sectional analysis highlighting internal structure, flow channels, and material distribution in our aluminum die castings.

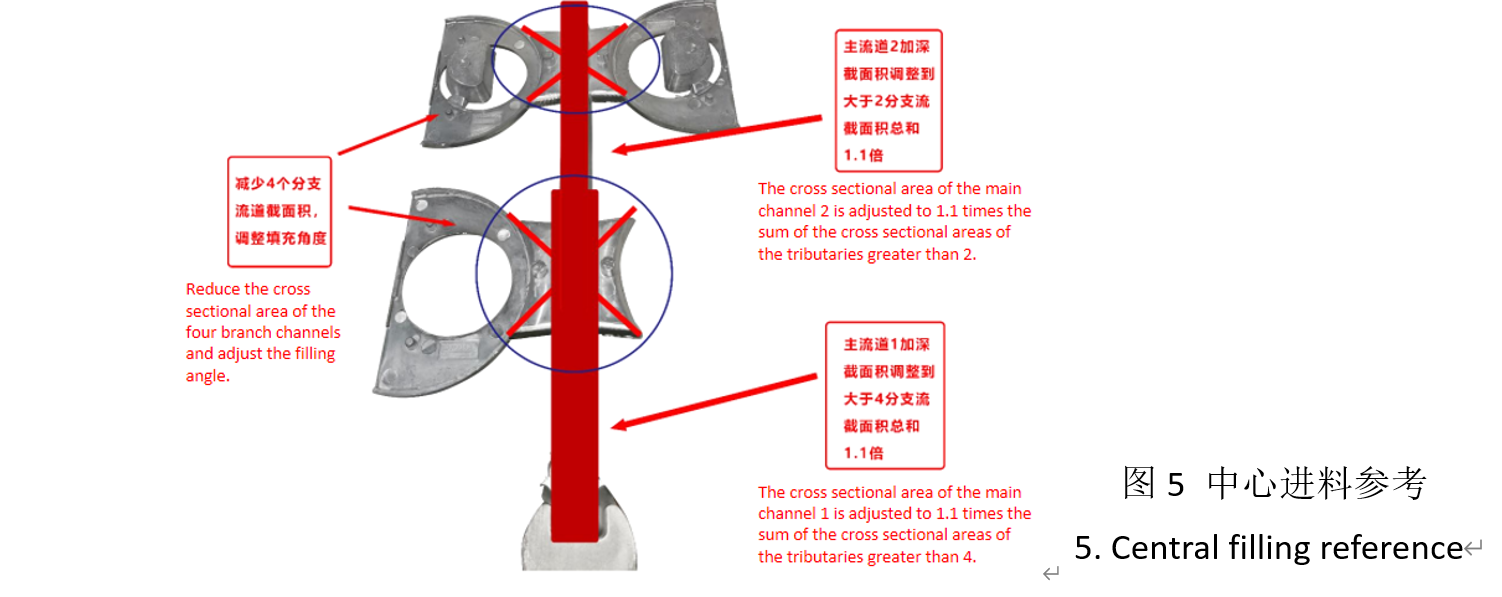

Figure 4: Improved gating system design with optimized main channel and branch flow paths to minimize air entrapment and ensure uniform filling.

Our aluminum die castings leverage state-of-the-art cold chamber die casting technology, ensuring precise control over material flow and solidification. This results in components with exceptional dimensional stability and structural integrity.

Through meticulous process optimization, our aluminum castings achieve a smooth, defect-free surface finish, eliminating issues like blistering during electroplating—a common challenge in standard die casting processes. This makes our products ideal for applications requiring high aesthetic standards or corrosion resistance.

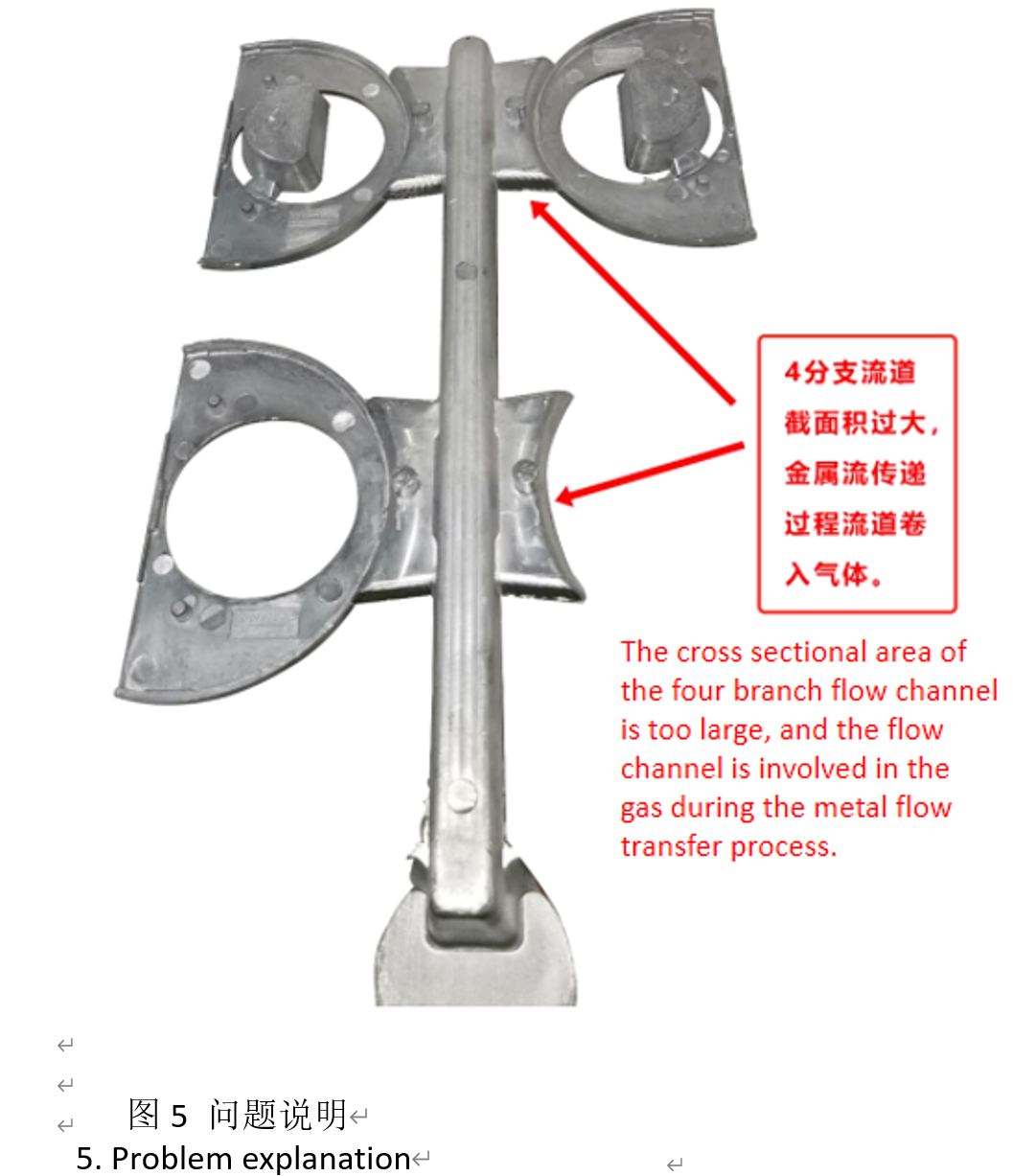

Our proprietary gating system design addresses critical flow dynamics:

- Main channel cross-sectional area engineered to exceed the sum of branch channels, minimizing gas entrapment

- Precision-adjusted filling angles for uniform material distribution

- Customized flow paths based on part geometry to prevent oxide skin formation

Equipped with oil-heated feeding pipes, our production line maintains optimal material temperature throughout the casting process, preventing heat loss that can compromise part quality. This ensures consistent melt viscosity and flow characteristics.

Unlike conventional aluminum die castings, our products offer:

- 30% reduction in post-processing defects (e.g., porosity, surface irregularities)

- Enhanced mechanical properties due to improved grain structure

- Greater compatibility with diverse surface treatments (electroplating, anodizing, powder coating)

- Longer tool life due to optimized process parameters

- Inspection: Conduct dimensional checks using calibrated measuring tools to verify compliance with specifications. Refer to Figure 3 for critical measurement points.

- Surface Preparation:

- Remove any residual release agents using a mild alkaline cleaner

- Perform light abrasive cleaning for electroplating applications to ensure adhesion

- Heat Treatment (If Required): Follow recommended temperature profiles for solution annealing or aging, based on the specific aluminum alloy used.

- Surface Finishing:

- For electroplating: Ensure parts are free of porosity (our optimized casting process typically eliminates this need)

- For painting: Apply compatible primers designed for aluminum substrates

- Assembly: Use torque specifications appropriate for aluminum to prevent thread stripping or deformation.

- Store in a dry environment with relative humidity below 60% to prevent oxidation

- Use non-abrasive packaging materials to protect surface finish

- Avoid prolonged exposure to temperatures above 120°C (248°F) before final processing

Our aluminum die castings are engineered for versatility across industries, providing reliable performance in demanding environments:

- Engine components (water pumps, oil pans)

- Transmission housings

- Suspension system parts

- Electrical system enclosures

- Heat sinks for power electronics

- Enclosures for industrial control systems

- Structural components for 5G infrastructure

- Lightweight structural brackets

- Hydraulic system components

- Avionics enclosures

- Valve bodies and manifolds

- Gearbox housings

- Robotics components

- Cost Savings: Reduced post-processing requirements and lower defect rates minimize production costs by up to 25% compared to standard aluminum castings.

- Time Efficiency: Consistent quality reduces inspection time and accelerates assembly processes.

- Design Flexibility: Ability to produce complex geometries with tight tolerances supports innovative product designs.

- Durability: Enhanced material properties ensure longer service life in harsh operating conditions.

- Regulatory Compliance: Products meet international standards, simplifying market access for global customers.

- Sustainability: Aluminum’s recyclability combined with our energy-efficient processes reduces environmental impact.

Our aluminum die casting processes and products adhere to stringent international standards, ensuring quality and reliability for global markets:

- ISO 9001:2015 (Quality Management System)

- IATF 16949:2016 (Automotive Quality Management)

- ASTM B85-17 (Standard Specification for Aluminum-Alloy Die Castings)

- RoHS Compliance (Restriction of Hazardous Substances)

- REACH Compliance (Registration, Evaluation, Authorization and Restriction of Chemicals)

We understand that each application has unique requirements. Our engineering team works closely with customers to develop tailored aluminum die casting solutions:

- Material Selection: Various aluminum alloys (e.g., A380, A383, A413) based on mechanical property requirements

- Part Geometry: Complex shapes with intricate details, supported by advanced CAD/CAM design

- Surface Finishes: Customized treatments including anodizing (clear, colored), powder coating, and electroplating

- Tolerance Requirements: Tight precision options down to ±0.01mm for critical dimensions

- Secondary Machining: Integrated milling, drilling, and tapping services for ready-to-assemble components

Our design-for-manufacturability (DFM) analysis ensures optimal casting performance while maintaining cost efficiency.

- Design and Engineering:

- 3D modeling and simulation of casting process

- DFM analysis to optimize part design for die casting

- Tooling design and fabrication using high-grade steel

- Material Preparation:

- Alloy melting and purification

- Precise temperature control (typically 650-700°C)

- Degassing to remove impurities

- Die Casting:

- Cold chamber die casting with automated process control

- Oil-heated feeding pipes to maintain optimal material temperature (as shown in our improvement measures)

- Optimized injection parameters for consistent filling

- Trimming and Deburring: Removal of sprues, runners, and flash

- Heat Treatment: Solution annealing and aging to enhance mechanical properties

- Finishing: Surface treatment per customer specifications

- In-process inspection at each production stage

- Coordinate Measuring Machine (CMM) for dimensional verification

- X-ray and ultrasonic testing for internal defect detection

- Surface roughness testing and visual inspection

- Tensile and hardness testing for material property verification

“The aluminum die castings from Niceday have significantly improved our production yield. Their attention to surface quality eliminated our electroplating issues, reducing scrap rates by 40%.”

— Automotive Components Inc., USA

“We needed a reliable supplier for complex aerospace components. Niceday’s customization capabilities and strict quality control made them the perfect partner. Their aluminum castings meet our stringent specifications consistently.”

— EuroAero Systems, Germany

“The optimized gating system in Niceday’s die castings has improved the performance of our hydraulic manifolds. We’ve seen a 25% reduction in pressure drop compared to our previous supplier.”

— Industrial Hydraulics Ltd., Australia

For standard parts, lead time is 4-6 weeks. For custom tooling and parts, lead time ranges from 8-12 weeks, depending on complexity.

Our standard MOQ is 4,000 pieces. For prototype or small-batch production, please contact our sales team for special arrangements.

Yes, we provide full material certificates (including alloy composition and mechanical properties) with each shipment. Additional testing reports can be provided upon request.

We maintain detailed process parameters for each part, conduct regular tooling inspections, and implement statistical process control (SPC) to ensure consistent quality across all production runs.

Our castings are compatible with a wide range of treatments including electroplating (chrome, nickel, zinc), anodizing (clear, black, colored), powder coating, and painting. We can recommend the best treatment for your specific application.

Absolutely. Our engineering team provides free DFM analysis for new designs, helping optimize part geometry for die casting, reduce costs, and improve performance.

We offer custom packaging solutions including bulk cartons, partitioned boxes, and palletized shipments. ESD packaging is available for electronic components.

Accepted payment methods: T/T (Telegraphic Transfer)

Available options: FOB, CFR, CIF, FCA

4000 Piece/Pieces

Ocean, Land, Air freight options available

NINGBO, SHANGHAI